Futuwear is an open source smart clothing service for occupational health. A team of Aalto University students are designing and implementing it with Futurice as a part of Aalto Protopaja summer course.

The student team has made a solid progress on Futuwear and successfully created a working prototype. Let’s look more closely at the architecture and sensors that are used in the prototype.

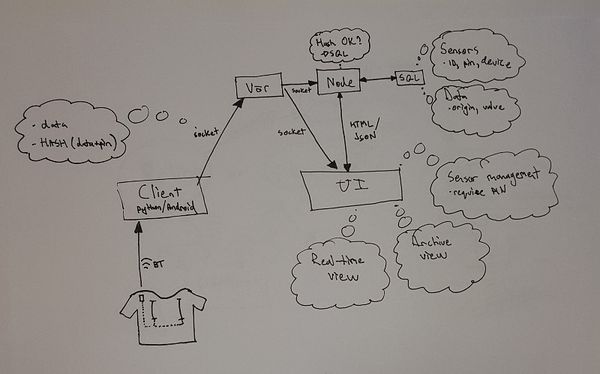

Architecture

Futuwear consists of clothing with sensors, a phone or a computer that functions as gateway, a Vör server born from our own Spice program which relays the sensor messages and a web server with a database for persistent storage of sensor data.

The clothing collects user posture sensor data and sends it via Bluetooth connection to a nearby Android or computer application. The application relays the data to a Vör server via SocketIO. The Vör server broadcasts these data messages to subscribers in the LAN. In this case one of the subscribers is the web server which stores the data to a database and another subscriber is a web application (served by the same web server) which visualizes the data in real time.

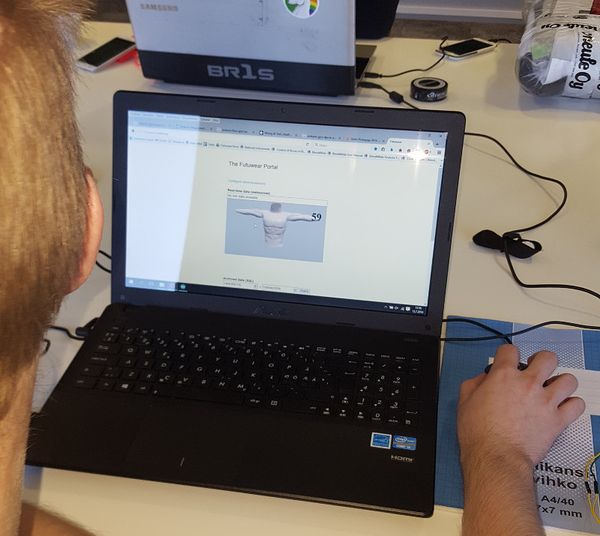

The team has made a cool 3D model of upper body and arms using Blender. The model moves in a web page according to the real time movements of the wearer of Futuwear.

Sensors

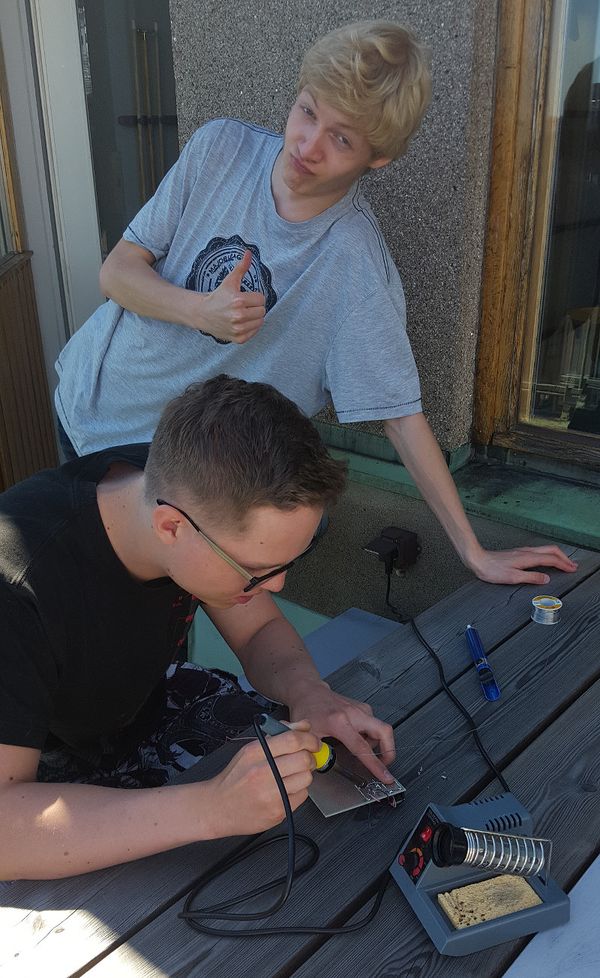

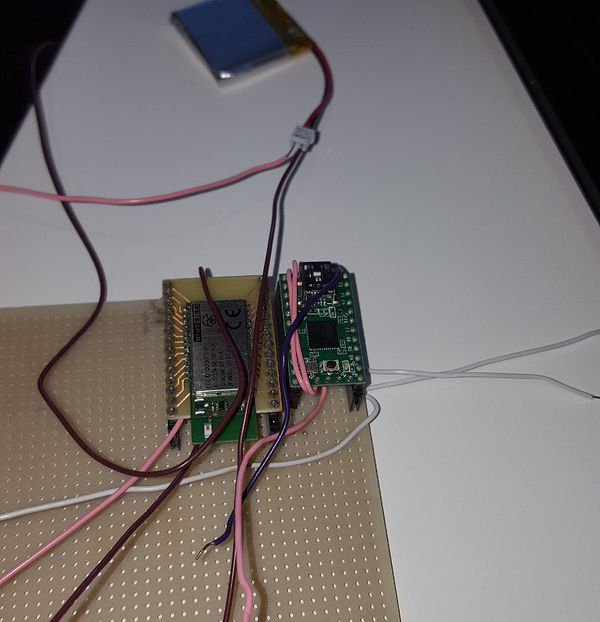

As the core of the sensor hardware the team uses the small Teensy microcontroller board which features multiple analog inputs. The small size of the microcontroller makes the circuitry less visible while the analog inputs are fit for reading data from multiple sensors. The team has connected a regulator to the board in order to use battery as a power source. The collected data is sent to a phone or a laptop with Bluegiga Bluetooth breakout board.

An early plan was to embed flex sensors in the clothing around joints locations and back to measure postures. Unfortunately the flex sensors turned out to be too rigid to adapt to different postures. They folded in wrong ways thus giving false signals. Therefore the team shifted to using conductive rubber cord which changes resistance when stretched. The rubber cord conforms to body movements better as it is not rigid like a flex sensor. Conductive thread woven into the clothing connects the rubber cords to the microcontroller.

Other types of sensors were evaluated during the project as well. One of the interesting ideas was to use EMG (electromyography, muscle sensor) to measure muscle tension, for example in the shoulder and neck areas. Unfortunately the idea was discarded because EMG was too unreliable.

The team still has a couple of other sensors such as pressure sensitive sheet and IMUs (gyroscope, magnetometer, accelerometer) at the their disposal. It is exciting to see if they come up with some creative ways to make use of them.

A suitable set of technologies has been selected and in the next couple of weeks we will see how the team evolves their prototype into a more polished service. In the next and final Futuwear blog post we will see the final product and discuss the concept/design of the service.

Links:https://protopaja.aalto.fi, Aalto Protopaja course (in Finnish)http://spiceprogram.org, Futurice open source programhttp://vor.space, Vör, a tool for smart office experiencehttps://www.pjrc.com/teensy, Teensy microcontrollerhttps://www.sparkfun.com/products/8606, Flex sensorhttps://www.adafruit.com/product/519, Conductive rubber cord

A 3D model in a web page visualising the body posture

A 3D model in a web page visualising the body posture

Soldering a regulator to a protoboard

Soldering a regulator to a protoboard

Bluegiga bluetooth module (left) and Teensy microcontroller (right) on a protoboard

Bluegiga bluetooth module (left) and Teensy microcontroller (right) on a protoboard

Futuwear clothing with conductive rubber cords and electrical wires visible

Futuwear clothing with conductive rubber cords and electrical wires visible

Kenta KusumotoSoftware Developer

Kenta KusumotoSoftware Developer