From IT Factories to Digital Ecosystems - Transforming The German Enterprise

The Global Digital Factory has been working with Futurice Digital Transformation at an early stage to help set up and evolve the Digital Factory structures.

The Global Digital Factory (GDF) is enabling Allianz companies to digitize and strengthen customer ties.

In 2016 Germany's trade surplus reached a new record of €252.9 billion ($270 billion), the largest gap between exports and imports since the country's statistical agency started keeping records. The German export motor is roaring like never before. But the export-driven "factory culture" responsible for this success might as well be an impediment for the county's digital transformation. It puts IT in the center of a push-based value chain system and thus hinders implementing a pull strategy necessary for the success of digital enterprise products and services.

The Deutschland Factory

Manufacturing has been the backbone of the German industry since WWII and before. A "Factory" is probably one of the first picture that comes to mind when people around the world talk about German economy. A huge, technologically advanced and well organized factory that creates products of supreme quality. The image goes even beyond factories to factories for building factories: Tesla's search for a partner to build "high-volume factories [that] allow us to manufacture high-quality products with economies of scale, making them more affordable and accessible to the world" resulted in November 2016 in "Tesla Grohmann Automation". Needless to say that the acquired "machine that builds the machine", as Tesla's official statement puts it, is a German engineering company (Grohmann Engineering).

The factory has not only been in the heart of the economy in Germany for decades, but also a cultural center piece in most rather large and global German enterprises. Everything in these enterprises starts in "The Factory" where incredible work is being done on how to create a superb product that then takes its way through the rest of the organisation and its distribution network out to the customer.

Interestingly this manufacturing centricity also applies to quite a few non-manufacturing companies in Germany. Large insurance companies for example have adopted a similar approach. Financial and insurance products and services are created in the center, pushed out to the operational belt to be localized and pushed out again to the (rather cascaded) distribution network and finally to the consumer. The enterprise acts as if there was an actual physical factory responsible for creating "German quality" products.

Holes In The Walls?

With the advancements of information technologies, non-technology enterprises started creating digital services and digital complementary products. And they mostly used the same approach of core product manufacturing to create and deploy the new products and services. In the same manner insurance companies used an "imaginary" factory to manufacture their financial products, actual manufacturing companies established virtual "IT factories" that created high quality digital products.

The factory-centered approach was designed to serve an economy of scale and it very much succeeded in that. However it is today one of the main obstacles as these enterprises are trying to conquer economies of speed and survive disruption of their business model. Breaking a few holes in the walls to enable "direct sales" for example cannot solve the structural issues tied to the factory approach: alienation, inflexibility and long product life cycles.

This is not digital transformation!

This is not digital transformation!

There is more to the factory approach than the intermediaries between the company and it's customers. The intermediaries are actually cascaded throughout the whole enterprise before anything leaves it. A typical German enterprise will have made considerable efforts in the last few years to "centralize" and "standardize" enterprise IT and pushed it to the heart of the company hoping to enable the cost effective creation of digital products and services.

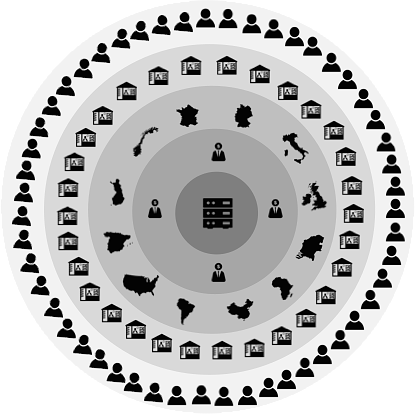

IT has been optimized for "pushing" out products and services and thus is becoming an impediment for digital transformation initiatives that are usually based on implementing a pull strategy. The following picture will look familiar to many people working in German global enterprises: a centralized IT is serving a few business departments in a group or holding headquarter. Those business departments are responsible for utilizing the new technologies to create new digital products and services and push them out to the semi-independent operation/sales entities around the globe. These entities will then push the new solutions to their distribution networks (brokers, dealers, agents) so the latters can use them to serve the customers.

Layers of factory-based production of digital services

Layers of factory-based production of digital services

Do you know what my favorite renewable fuel is? An ecosystem for innovation.

Thomas Friedman

From IT Factories to Digital Ecosystems

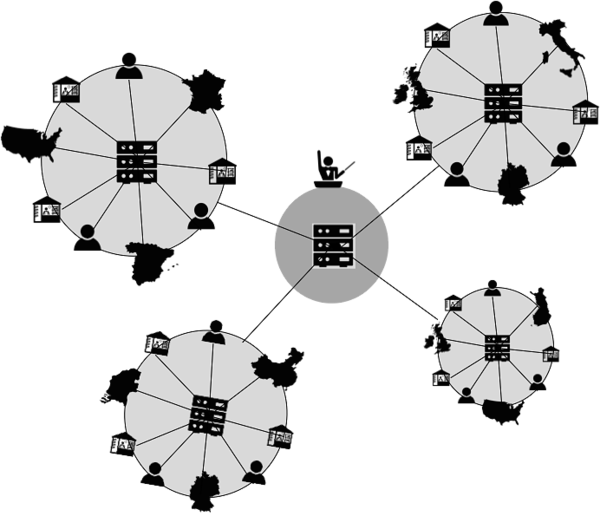

Gartner defines a digital ecosystem as an “interdependent group of actors sharing standardized digital platforms to achieve a mutually beneficial purpose.” In this context, we see ecosystems as autonomous communities formed and managed by stakeholders from all layers of the erstwhile factory-based production realm. These communities operate in the global ecosystem world, share the same language and use different approaches/tools/platforms to identify, develop, test / pilot new solutions. They are based on collaboration and co-creation and are focused on human needs and added value in a specific solution space. Customers and intermediaries (dealers, agents, brokers) are an inherent part of these ecosystems. This new approach that contributed to the success of very inspiring companies like Netflix (highly aligned, loosly coupled) or Etsy and which is the base of every larger open source project or foundation (e. g. Cloud Foundry) addressed the main internal obstacles to digital innovation in large global enterprises:

- The "not invented here"

- The "not incentivized"

- The "no technical standard yet"

- The "no cross-financing between entities"

- The "not my KPI"

Digital ecosystems in a global enterprise

Digital ecosystems in a global enterprise

So many technologies start out with a burst of idealism, democratization, and opportunity, and over time, they close down and become less friendly to entrepreneurship, to innovation, to new ideas. Over time, the companies that become dominant take more out of the ecosystem than they put back in.

Tim O'Reilly

Time To Tear Down The Walls

Digital transformation is not about modernizing or the technological advancement of the "heart" of the factory, but rather the recostruction of the whole factory-based enterprise starting with tearing down the walls between the silos. Technology (mobile, cloud, big data, VR, blockchains, AI, IoT etc.) is not the "new motor" of digital production nor is it the "new assembly line" for manufacturing high-quality digital services. Techology is just one part in a larger set of tools (including people, culture, organisation, know-how etc.) that enable building a new type of products which is driven by new values. It is these new values (customer delight, ease-of-use, continous improvement) that drive the success of today's and tomorrow's services and products. Whether those are enabled, supported or created by the mentioned technologies might not be a minor issue, but it is not the main one.

Read the next post in the series about Building Digital Ecosystems in a Large Enterprise.

This article is part of a series designed to help enterprises become more lean. We’re partnering with Lean Enterprise co-author, Barry O’Reilly, to host executive roundtable sessions in London and Berlin, as well as an event in Helsinki, ‘Lean Rocks’, all during February and March. Futurice and Barry will be offering bespoke training and workshops with clients in Helsinki and Tampere, if you’re interested in learning more about this please contact Timo Hyväoja.

Raid NaimHead of Digital Transformation

Raid NaimHead of Digital Transformation- Telina ReilGlobal Digital Factory Manager, Allianz SE